Leveraging Machine Learning for Predictive Maintenance in Salvage Yards: 247betbook, Radhe exchange login, World 777 id

247betbook, radhe exchange login, world 777 id: In today’s fast-paced world, technology is constantly evolving and transforming various industries. One of the most significant advancements in recent years is machine learning, a subset of artificial intelligence that enables computers to learn and improve from experience without being explicitly programmed. This technology has the potential to revolutionize many sectors, including salvage yards.

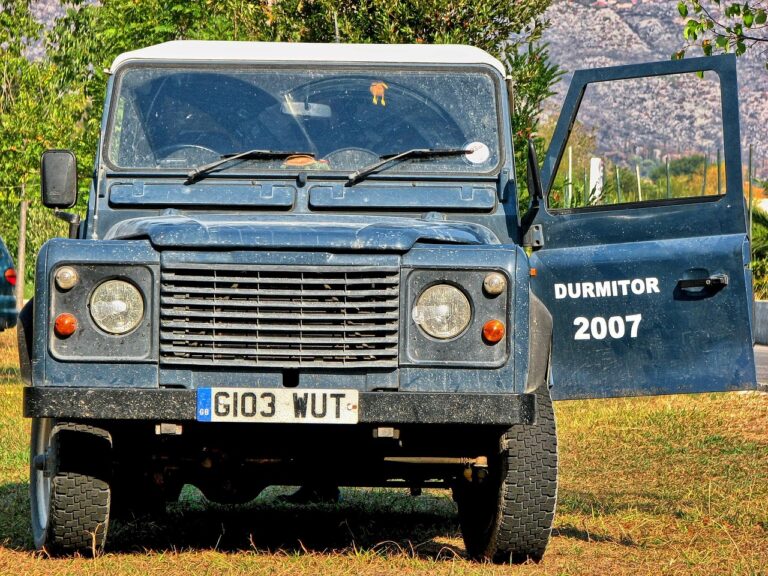

Salvage yards, also known as junkyards or scrap yards, play a crucial role in the recycling and disposal of end-of-life vehicles and other scrap materials. These facilities collect, dismantle, and recycle vehicles to recover valuable components and materials. However, maintaining and managing the equipment and machinery in salvage yards can be a challenging task.

Predictive maintenance is a proactive approach to maintenance that uses data analytics and machine learning algorithms to predict when equipment is likely to fail so that maintenance can be performed at the optimal time. By leveraging machine learning for predictive maintenance in salvage yards, operators can minimize downtime, reduce maintenance costs, and improve overall operational efficiency.

Here are some key ways in which salvage yards can benefit from leveraging machine learning for predictive maintenance:

1. Improved Equipment Reliability: Machine learning algorithms can analyze equipment sensor data in real-time to identify patterns and trends that may indicate potential equipment failures. By predicting when equipment is likely to fail, operators can perform maintenance before a breakdown occurs, reducing the risk of unplanned downtime.

2. Optimal Maintenance Scheduling: Machine learning algorithms can also optimize maintenance schedules based on equipment usage, environmental conditions, and other factors. This ensures that maintenance is performed at the right time, maximizing the lifespan of equipment and minimizing maintenance costs.

3. Cost Savings: Predictive maintenance can help salvage yards save money by reducing the need for emergency repairs and eliminating unnecessary maintenance tasks. By addressing issues before they escalate, operators can avoid costly repairs and keep equipment operating at peak performance.

4. Increased Efficiency: By reducing downtime and improving equipment reliability, salvage yards can increase operational efficiency and productivity. This allows operators to process more vehicles and materials, leading to higher profits and a more sustainable business model.

5. Enhanced Safety: Predictive maintenance can also improve safety in salvage yards by identifying potential safety hazards before they cause accidents or injuries. By maintaining equipment in optimal condition, operators can create a safer work environment for employees and reduce the risk of accidents.

Overall, leveraging machine learning for predictive maintenance in salvage yards can help operators streamline operations, reduce costs, and improve overall efficiency. By harnessing the power of data analytics and artificial intelligence, salvage yards can stay ahead of the competition and continue to thrive in the rapidly changing recycling industry.

**FAQs**

1. What is predictive maintenance?

Predictive maintenance is a proactive maintenance strategy that uses data analytics and machine learning algorithms to predict when equipment is likely to fail so that maintenance can be performed at the optimal time.

2. How does machine learning improve predictive maintenance in salvage yards?

Machine learning algorithms analyze equipment sensor data to identify patterns and trends that may indicate potential equipment failures. By predicting when equipment is likely to fail, operators can perform maintenance before a breakdown occurs, reducing downtime and maintenance costs.

3. What are the benefits of leveraging machine learning for predictive maintenance in salvage yards?

Some benefits of leveraging machine learning for predictive maintenance in salvage yards include improved equipment reliability, optimal maintenance scheduling, cost savings, increased efficiency, and enhanced safety.

4. How can salvage yards implement predictive maintenance using machine learning?

Salvage yards can implement predictive maintenance using machine learning by collecting and analyzing equipment sensor data, training machine learning algorithms to predict failures, and integrating predictive maintenance practices into their existing maintenance workflows.

5. What are some challenges of implementing predictive maintenance in salvage yards?

Some challenges of implementing predictive maintenance in salvage yards include the initial cost of data collection and analysis, resistance to change from traditional maintenance practices, and the need for skilled data analysts and maintenance technicians to interpret and act on predictive maintenance insights.